Ingraham by Jeffrey Stephenson

July 23, 2009 | 10:03

Exterior

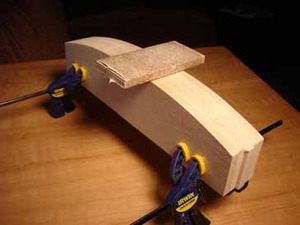

The remainder of the case was sheathed in aircraft grade birch plywood using small nuts and bolts. I created a series of identical supports that I call “rafters” that provide the underlying structure of the curved roof. After analysing a photo of the original radio’s top curve I free hand carved a wooden master curve using wood saws and sandpaper.

The remaining rafters were duplicated from the master curve. These rafters were made from basswood, a hardwood native to Michigan, USA that is lightweight and easy to shape. The case’s top was formed by first fitting the rafters to the case top and then using contact cement to glue down a thin sheet of aircraft grade plywood across the supports.

I normally use only water-based, non-toxic adhesives like yellow carpenters glue but in this case I needed the strength of contact cement to hold down a large curved stressed piece like the top.

I covered the case’s outer plywood surface in American black walnut veneer. Individual pieces of veneer were cut, glued up, clamped down to dry. I cut the veneer slightly larger than the area to be covered and this excess is subsequently trimmed using emery boards stolen from my wife. The back of the case sports a piece of semi-rare figured black walnut veneer.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.